Jaguar XJ6 SIII 7" headlamp conversion

Here is how I went about upgrading my wife's 1985 Jaguar Series III XJ6 to

have the 7" outer headlights that the designers intended. I bought some

used trim rings on eBay from someone in England; some new WIPAC plastic

repro 7" headlamp buckets; and some new headlamp wiring harnesses. Most

people probably re-use their existing headlamp wiring, and that is easier

in some ways, but I decided if I was going to go to all this effort, I

wanted to swap out complete units with all new parts. I just ordered TR6

repro harnesses from a TR vendor, but they're all the same, you could get

them from any supplier.

First, let's see why we'd even want to do this, with a look at the car

before and after the conversion:

|

Before

After

Wow, doesn't the US-spec version look pretty dumb? What were they

thinking? It's gotta be Ralph Nader's fault, I just know it.

Let's take a closer look before and after:

|

Before

After

|

Here are just the rings, so you can see the difference:

|

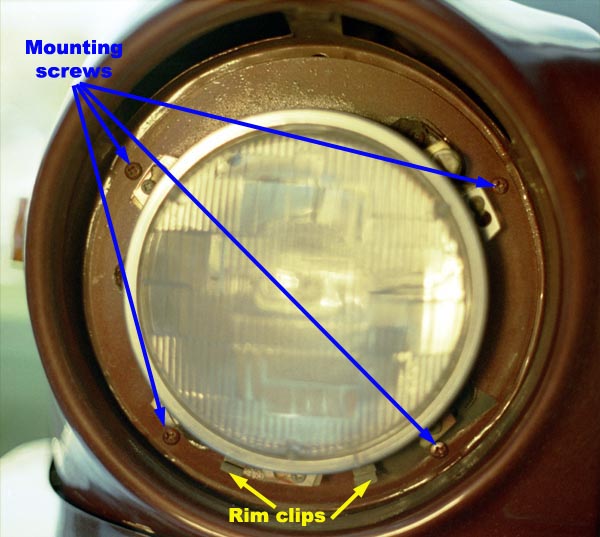

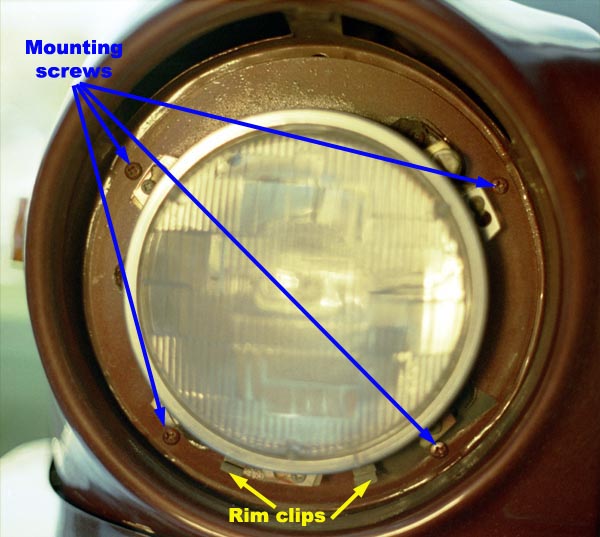

I started by removing the trim ring on an outer headlight. Just remove the

flathead screw up at the top center, and the ring will pull right away,

unclipping from the little metal clips at the bottom as it comes. Then I

removed the 4 mounting screws that hold the adapter plate and headlamp

bucket to the fender. (There is no need to remove the headlamp bucket from

the adapter plate.) If you were planning to re-use your existing wiring,

then before you remove the bucket, you should remove the headlight from the

bucket, remove the wires from the connector, and push the wires and the

rubber plug out from the old headlamp bucket. In my case I just let it

dangle on the wires after removing it, before proceeding to the next step.

Here is what you'll see after removing the original trim ring:

|

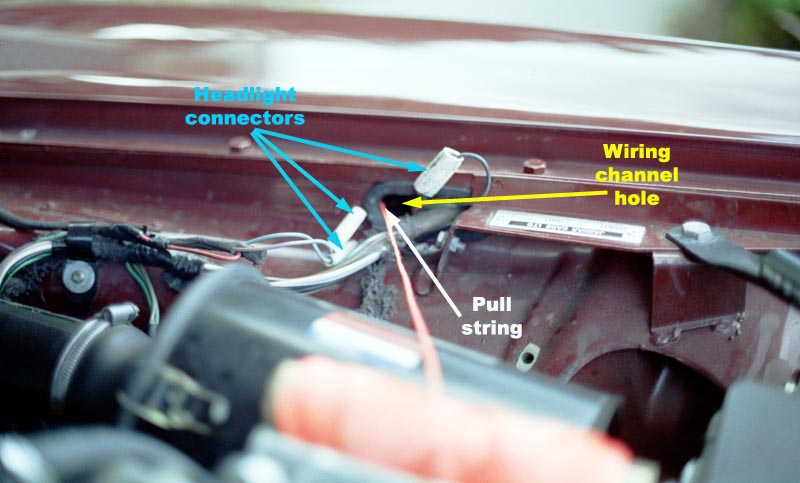

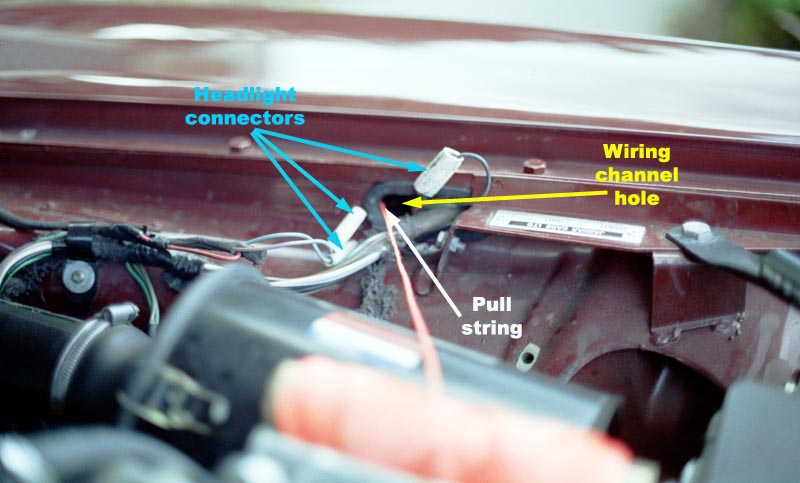

Since I wanted to install new wiring, it meant removing the old stuff. But

it runs through a blind channel in the fender, up into the engine

compartment where the connections are made. That's no fun! So I

disconnected the bullet connectors that were hanging out right at the hole

in the fender in the engine compartment, then tied a strong string around

all of them in such a way that it couldn't possibly pull off. Then, working

in the wheelwell, I pulled the harness and string back from the engine

compartment to the wheelwell, then working from the front of the car, I

pulled the bucket and harness and string forward and out the headlamp

opening. The right angle turn in the wheelwell makes it impossible to just

pull from the front in one go; you have to do it in two steps like this.

The result is a completely removed old bucket, and a string sitting there

ready to be able to pull the new wires back up to the engine compartment.

Here is the view from the engine compartment at this stage. On the left

side of the car, you need to remove the headlamp fuse panel and push it to

the side to be able to do this step.

|

|

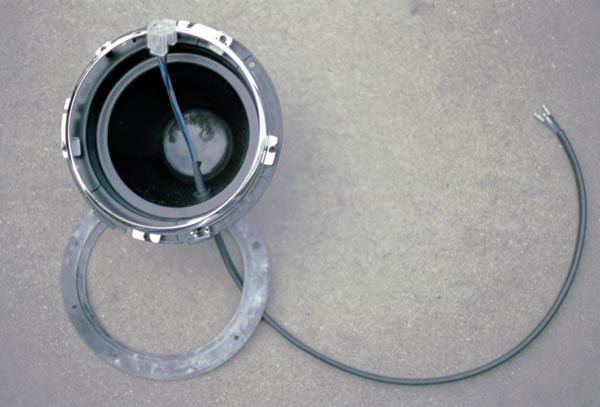

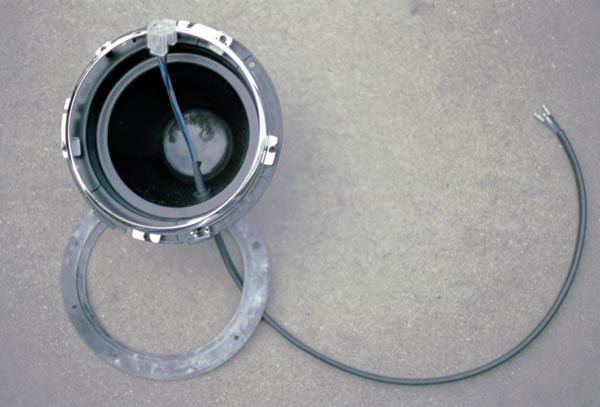

Here is the WIPAC plastic repro bucket, with TR6 wiring harness already

installed. I made sure the plastic sheathing on the wires (not just the 3

wires) was in the rubber plug, with the pointy part of the plug facing

towards the bullet connector end of the wires. I fed the wire shank

through the hole in the bucket, bullet ends first, from the inside towards

the outside. I used some soapy liquid (OK, you got me, I used Windex

because it was at hand...) to lube up the rubber plug, then pulled and

twisted until it had popped through the hole in the bucket and seated in

the ridge in the rubber plug. Remember to keep the sheathing in the plug;

if you let it slip until just the separate wires are going through the

plug, it won't seal out the elements. (This is more than likely the state

you found your original buckets in by the way!)

|

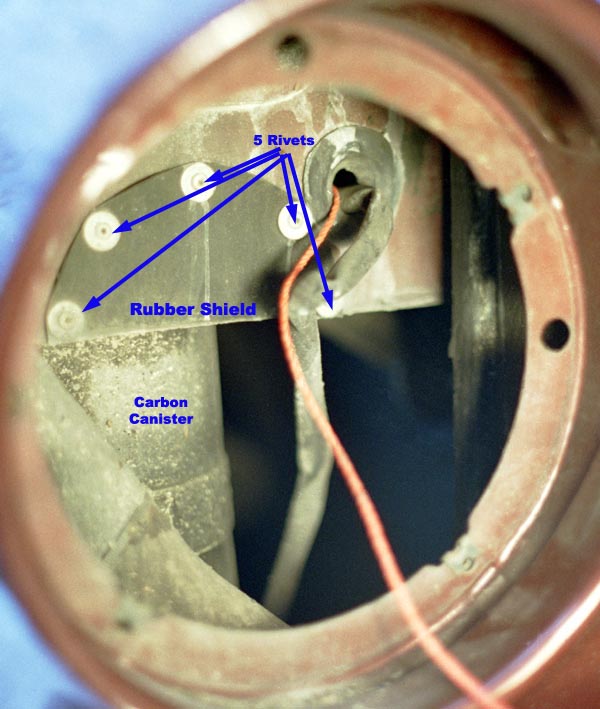

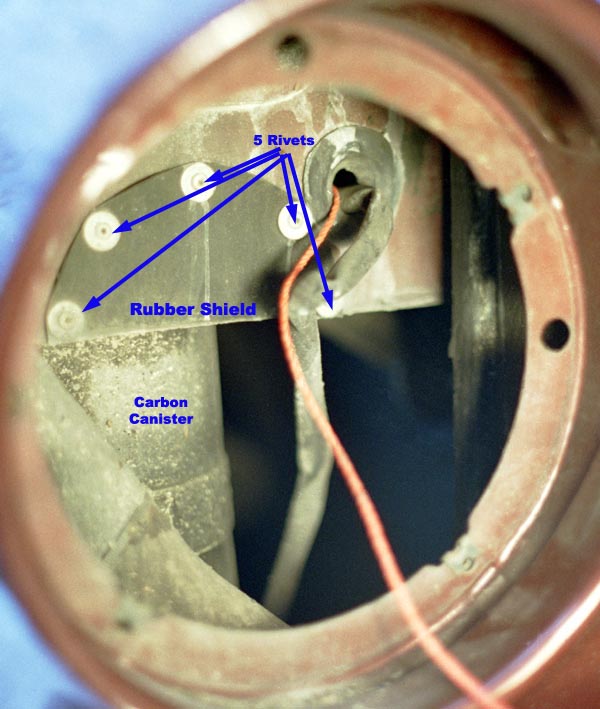

Here's where it got interesting because of the WIPAC buckets and the fact

that they stick so far out towards the back. There is a rubber sheet

riveted to a plate behind the headlights. I guess the idea is to have a

hole for the buckets to nestle back into, but with the rubber sheet to

prevent road splash from making its way up into the bucket through the

wiring rubber plug, which comes out the top. The rubber sheet would

actually move out of the way as designed when the too-long bucket hit it,

but those washers under the rivets jut into the opening and foul with the

bucket. So I simply drilled out all 5 rivets and removed the washers and

the rubber sheet and called it good. The plastic bucket should have no

problems with road splash anyway. But in any event, your life would be

simpler with an original metal bucket. (And even easier still if you have

an actual Jaguar bucket with the bottom clips for the trim ring! But I'm

getting ahead of myself...)

Here's what you'll see once the old bucket is removed (this is the right

side headlight):

|

The original setup had the adapter plate screwed right onto the fender,

with the isolation gasket going between the headlamp bucket and the adapter

plate. Because this bucket screws to the fender with an isolation gasket,

the original screws wouldn't quite reach through the additional thickness

of the gasket, plus my solution to the bottom clip problem also required

more screw length. So I simply bought some longer ones from the hardware

store.

Here is the new bucket installed, before I figured out I even had a bottom

clip problem:

|

The original trim rings are held in place on the bottom with springy metal

clips that lodge in grooved tabs on the trim rings. The US-spec clips are

spaced more narrowly than the larger ring tabs, so I couldn't just un-rivet

the spring clips from the old bucket and attach them to the new one. But

happily, the large ring's grooved tabs are exactly in line with the lower

mounting screws for the bucket! So I bent up some stiff wire into a clip

shape, with an eyelet to go under the lower mounting screws. I actually

used old pinball machine ball guides for my wire stock(!) but you could use

wire stock from the hardware store, or perhaps even a cut up clothes

hanger. The idea is to have a shaft in the right position to lodge in the

grooves in the tabs of the rings just to keep them roughly in place; the

upper mounting screw still provides the main means of keeping the ring

attached to the car.

Here is a close-up of an installed clip; I hope you can get the idea of how

to make them from this:

|

|

OK, finally, here is the finished installation:

|

|

And once more, let's remind ourselves why we wanted to do this:

|

Ahhhhhhhhhhh, pretty kitty!!!

Ahhhhhhhhhhh, pretty kitty!!!